-

call us

0086 13559245184 -

email us

sales@fortunepart.com

call us

0086 13559245184email us

sales@fortunepart.comMar, 2025

Introduction, Working Principle, and Maintenance Tips for Komatsu Excavator Hydraulic Cylinders

Introduction:

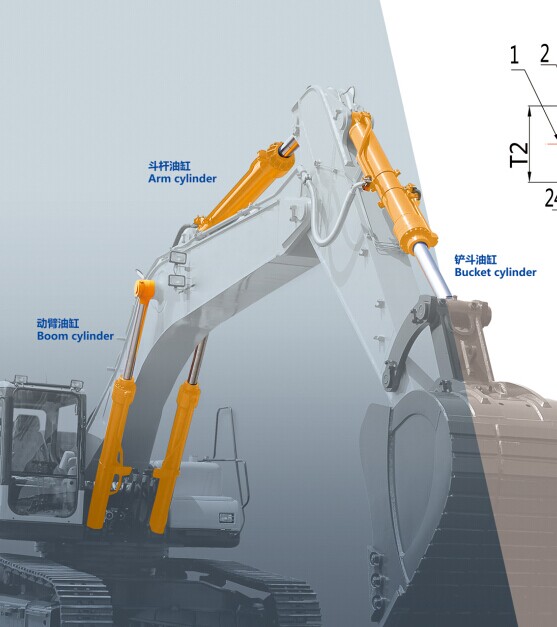

Komatsu excavator hydraulic cylinder includes boom cylinder, arm cylinder(stick cylinder) and bucket cylinder.

Komatsu excavators are renowned for robust construction and efficient operation in the construction industry. A crucial component of these machines is the hydraulic cylinder, which plays a vital role in their functionality. In this blog post, we will explore the features, working principle, and maintenance tips for Komatsu excavator hydraulic cylinders, focusing on maximizing performance and longevity.

I. Hydraulic Cylinder Overview:

Hydraulic cylinders in Komatsu excavators are responsible for converting hydraulic power into mechanical force, facilitating various movements, such as digging, lifting, and tilting. They are designed to withstand heavy loads and provide precise control for enhanced productivity on construction sites. The specific model of the excavator discussed in this post is the Komatsu PC220-10 hydraulic excavator.

II. Working Principle:

Komatsu excavator hydraulic cylinders operate based on the principles of Pascal's law and hydraulic pressure. When hydraulic fluid is pumped into the cylinder, it applies pressure to the piston, generating force. This force is then transmitted to the component or attachment connected to the cylinder, allowing for precise and controlled movement. By controlling the flow of hydraulic fluid, operators can maneuver the excavator with accuracy and efficiency.

III. Maintenance Tips:

Conclusion:

The hydraulic cylinders in Komatsu excavators, such as the PC220-10 model, are critical components that enable precise and efficient movements during construction operations. Understanding their working principle and implementing proper maintenance practices can significantly enhance their performance, extend their lifespan, and minimize downtime. By regularly inspecting and maintaining the hydraulic cylinders, operators can optimize the productivity and reliability of Komatsu excavators on various job sites.

categories

recent posts

tags

Xiamen Fortune Industrial Co., Ltd.

Room 402,No.7,Kangleli,Huli District, Xiamen, Fujian, China

Tel : 0086 13559245184

Fax : 0086-592-7072790

Whatsapp/Wechat : +8613559245184

Contact Person: James Xie

E-mail: sales@fortunepart.com

Microsoft Teams: part-sales

scan to wechat: